Stainless Steel Round Bar

- Bars-001

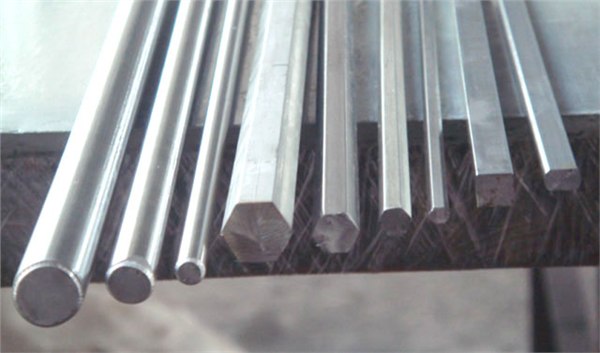

- Stainless steel bars stainless steel square bars stainless steel hex bar are the star products.

- cold drawn, hot rolled and forged stainless steel are available by request.The stainless steel bar offered by BIG have beautiful surface and good tolerance in h11 and h9.

Standards: ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311 and JIS G 4318

Stainless steel bars including stainless steel round bar,stainless steel square bar,stainless steel hex bar,stainless steel angle abr,stainless steel flat bar are the main products of exsteel Industry group. Stainless steel bars usually used in construction field, ships building industry and many various machinery and hardware fields. The ISO 9001 management system ensure the high quality of the products. exsteel Industry Group cooperated with many world class famous company in this field!

Materials:

300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347,

200series:201,202,202cu,204;

400series:409,409L,410,420,430,431,440;

Others:2205,2507,2906,330,660,630,631,17-4ph,17-7 ph,904L,et.

Surface:

Black;Pickled;HL;Brushed;Polished

Technical treatment:

cold drawn /hot-rolled/hot-forged

Normal length: 1000 to 6000mm

Tolerance: h9&h11

Dimensions:

Hot-rolled: Ø5.5 to 110mm

Cold-drawn: Ø2 to 50mm

forged: Ø110 to 500mm

Applications:

Construction field, ships building industry

Decoration materials and outdoor publicity billboard

Bus inside and outside packaging and building and springs

Handrails, electroplating and electrolyzing pendants and foods

Corrosion- and abrasion-free to meet specific requirements of various machinery and hardware fields

Production procedure:

raw elements (C, Fe, Ni, Mn, Cr and Cu), smelted into ingots by AOD finery, hot rolled into black surface, pickling into acid liquid, polished by automatically machine and cutting into pieces

Grade:

| Grade and Main chemical composition% | |||||||||

| C | Si | Mn | P≤ | S≤ | Cr | Mo | Ni | Other | |

| 201 | ≤0.15 | ≤1.00 | 5.5-7.5 | 0.06 | 0.03 | 16-18 | - | 3.5-5.5 | N≤0.25 |

| 202 | ≤0.15 | ≤1.00 | 7.5-10.0 | 0.06 | 0.03 | 17-19 | - | 4.0-6.0 | N≤0.25 |

| 301 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | - | 6.0-8.0 | - |

| 302 | ≤0.15 | ≤1.00 | ≤2.00 | 0.2 | 0.03 | 17-19 | - | 8-10.0 | - |

| 303 | ≤0.15 | ≤1.00 | ≤2.00 | 0.045 | ≥0.015 | 17-19 | ≤0.6 | 8.0-10.0 | - |

| 304 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 8-10.5 | - |

| 304L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | - | 9-13 | - |

| 305 | ≤0.12 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 10.5-13 | - |

| 309S | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 22-24 | - | 12-15 | - |

| 310S | ≤0.08 | ≤1.5 | ≤2.00 | 0.045 | 0.03 | 24-26 | - | 19-22 | - |

| 316 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2-3 | 10-14 | - |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 16-18 | 2-3 | 12-15 | - |

| 317 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 3-4 | 11-15 | - |

| 317L | ≤0.03 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 18-20 | 3-4 | 11-15 | - |

| 321 | ≤0.08 | ≤1.00 | ≤2.00 | 0.045 | 0.03 | 17-19 | - | 9-13 | Ti≥5×C |

| 405 | ≤0.08 | ≤1.00 | ≤1.00 | 0.04 | 0.03 | 11.5-14.5 | - | ≤0.6 | AL0.1-0.3 |

| 420F | 0.26-0.4 | ≤1.00 | ≤1.25 | 0.06 | ≥0.15 | 12-14 | ≤0.6 | ≤0.6 | - |

| 430 | ≤0.12 | ≤0.75 | ≤1.00 | 0.04 | 0.03 | 16-18 | - | ≤0.6 | |

Packing:

plastic poly-bag, wooden case

All exsteel's products are packed, stored, transported according to the international regulation.

The square bars are wrapped with anti-rust paper and steel rings to prevent damage. Identification labels are tagged according to standard specification or customer's instructions. Special packing is available as per customer's requirement.Ply wooden box are available for special protection. Other kinds of packing can be offered if request.